In high-risk industrial environments where safety is paramount, Triconex safety systems have become the gold standard for critical process protection. As a leading Triple Modular Redundancy (TMR) technology provider, Triconex—now part of Schneider Electric—delivers unmatched reliability for industries where failure is simply not an option.

What is Triconex TMR Technology?

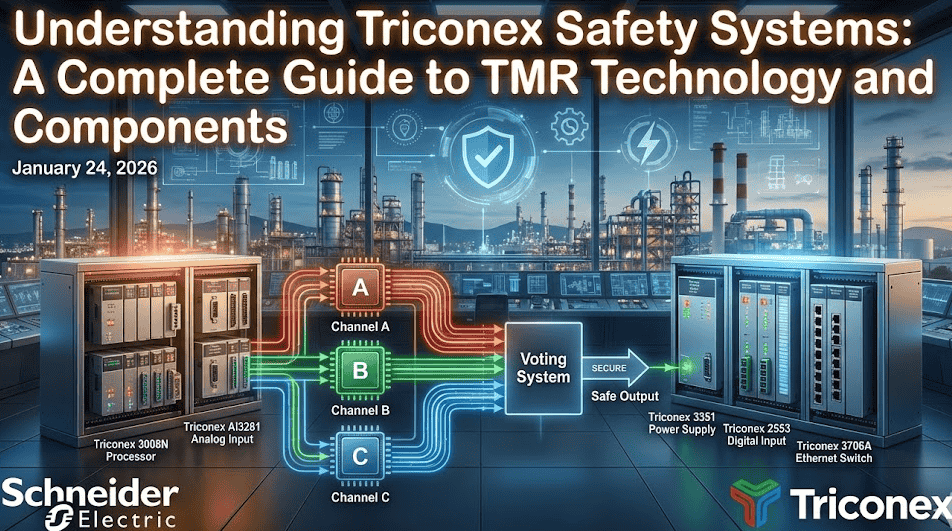

Triconex pioneered the Triple Modular Redundancy architecture, a fault-tolerant design that uses three independent processing channels operating in parallel. Each channel processes the same inputs simultaneously, and a voting system compares the outputs. If one channel fails or produces an incorrect result, the other two channels continue operating seamlessly—ensuring zero downtime and continuous safety protection.

This TMR architecture is the foundation of Safety Instrumented Systems (SIS) that meet the most stringent safety integrity levels, including SIL 3 certification for critical applications.

Key Components of Triconex Safety Systems

Main Processors

The heart of any Triconex system is its main processor module. The Triconex 3008N Main Processor represents the core computing power of the Tricon system, handling all logic execution and communication tasks. For enhanced performance requirements, the Triconex 3009 High-Performance Control Module offers increased processing speed and memory capacity.

The Trident platform features advanced processors like the Triconex MP3101 S2 Main Processor Module, designed specifically for modern safety control systems requiring high-speed data processing and extensive I/O capabilities.

Power Supply Modules

Reliable power is essential for safety systems. The Triconex 3351 Power Supply Module provides stable, redundant power for Tricon controllers, while the Triconex 8305A Power Supply serves the Trident platform with enhanced power management features.

Digital I/O Modules

Triconex offers comprehensive digital input and output solutions for safety applications. The Triconex 2553 Digital Input Module captures field signals from safety devices, while the Triconex 2652 Digital Output Module controls final elements like shutdown valves and emergency stops.

For higher channel density, the Triconex 3503N 32-Channel Digital Input Module provides expanded input capacity, and the Triconex 3625A Digital Output Module delivers reliable output control for critical safety functions.

Analog I/O Modules

Process variables like temperature, pressure, and flow require precise analog measurement. The Triconex AI3281 Analog Input Module provides high-accuracy signal acquisition, while the Triconex 3481 Analog Output Module enables precise control of proportional valves and variable speed drives.

Communication Modules

Modern safety systems require seamless integration with plant networks. The Triconex 3201 Communication Module enables connectivity with DCS systems and SCADA networks, while the Triconex 3706A Ethernet Switch Module provides industrial-grade network switching for distributed architectures.

Triconex System Platforms

Tricon CX

The Tricon CX platform represents the latest generation of Triconex safety controllers. With the Triconex 2101 CX Controller Module at its core, this platform offers enhanced cybersecurity features, increased processing power, and simplified maintenance procedures.

Trident

The Trident platform combines safety and critical control in a single system. Featuring processors like the Triconex MP3101 Trident Redundant Processor, it delivers both SIS and process control capabilities while maintaining full TMR redundancy.

Industry Applications

| Industry | Application | Safety Function |

|---|---|---|

| Oil & Gas | Offshore platforms, refineries | Emergency shutdown, fire & gas detection |

| Chemical | Process plants, reactors | Overpressure protection, runaway reaction prevention |

| Power Generation | Turbine control, boiler protection | Turbine trip, burner management |

| Pharmaceutical | Batch processing, clean rooms | Process interlocks, environmental control |

| Nuclear | Reactor protection systems | Reactor trip, containment isolation |

Why Choose Triconex for Safety Applications?

- Proven Track Record: Over 40 years of deployment in critical applications worldwide

- SIL 3 Certified: Meets the highest safety integrity levels for process industry applications

- Zero Unplanned Shutdowns: TMR architecture ensures continuous operation even during component failures

- Cybersecurity: Built-in security features protect against cyber threats

- Global Support: Schneider Electric provides worldwide service and spare parts availability

Maintenance and Spare Parts

Maintaining Triconex systems requires access to genuine spare parts and qualified service. Critical spares like the Triconex 4117 CPU Processor Module and Triconex 4119A Enhanced Intelligent Module should be kept in inventory to minimize downtime during maintenance activities.

Termination panels and field wiring components, such as the Triconex 9561-810 Digital Input Termination Panel and Triconex 7400056-380 Terminal Board, are essential for maintaining proper field connections.

Conclusion

Triconex safety systems represent the pinnacle of industrial safety technology. Whether protecting offshore oil platforms, chemical reactors, or power generation facilities, the TMR architecture delivers the reliability and availability that critical processes demand. With comprehensive product lines spanning processors, I/O modules, power supplies, and communication interfaces, Triconex provides complete solutions for any safety application.

For facilities requiring the highest levels of safety integrity, Triconex remains the trusted choice for engineers and operators worldwide.