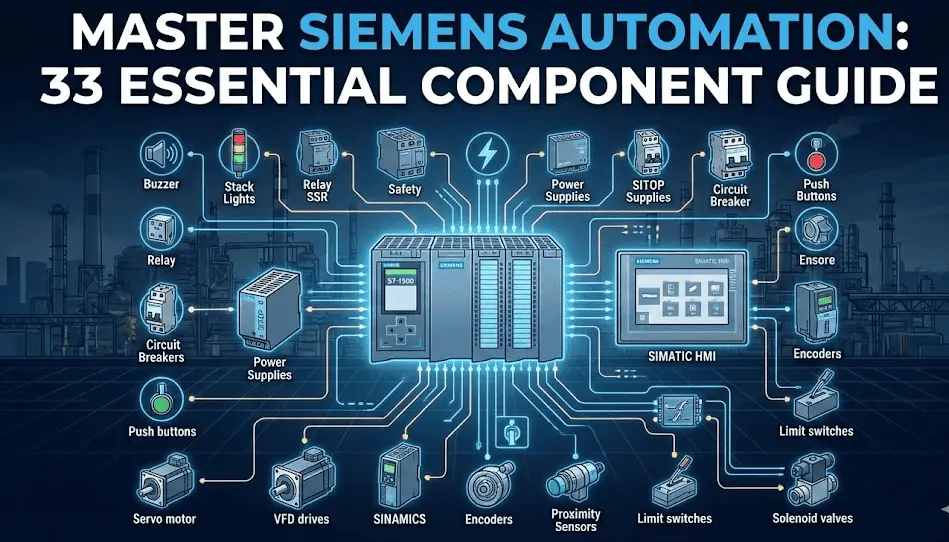

Want to master Siemens industrial automation? Understanding these 33 essential components is the key. Whether you are an automation engineer, maintenance technician, or PLC programmer, this guide covers all the fundamental elements you need to know.

Signal & Indication Components

1. Buzzer

Used for audible alarms and notifications. Essential for safety warnings in industrial environments. Typically connected to PLC digital outputs for programmed alerts.

2. Indicator Light

Displays equipment status or signals. Available in various colors (red, green, yellow, blue) for different states like running, stopped, or fault conditions.

3. Three-Color Stack Light

Multi-color tower lights indicating machine status – typically red (fault), yellow (warning), green (running). Essential for quick visual status identification on factory floors.

Relay & Switching Components

4. Intermediate Relay

Used for signal amplification and conversion, enabling multi-circuit control in complex systems. Bridges the gap between low-power PLC outputs and high-power loads.

5. Safety Relay

Critical for safety circuits, ensures equipment stops safely during faults. Required for CE compliance and functional safety standards like SIL and PL ratings.

6. Solid State Relay (SSR)

Contactless relay for high-speed switching applications with longer lifespan than mechanical relays. Ideal for frequent switching operations.

7. Time Relay

Provides delayed action based on preset time. Used for sequential control and timing applications. Siemens offers modules like the G34924-K2200-H1 for industrial timing functions.

8. Protection Relay

Monitors electrical parameters and protects equipment from faults. The Siemens 7SJ5311-4EA02-1AA0 provides numerical protection for medium voltage applications.

Power & Protection Components

9. Switching Power Supply

Converts AC to stable DC power for PLC and control systems. The Siemens SITOP series, such as the 6EP1337-3BA00, is an industry standard for reliable 24V DC power delivery.

10. Molded Case Circuit Breaker (MCCB)

Provides overload and short-circuit protection with manual switching capability. Used for main power distribution in control cabinets.

11. Miniature Circuit Breaker (MCB)

Automatic circuit protection for overload and short circuits in control panels. Available in various current ratings for branch circuit protection.

12. Surge Protector

Protects sensitive equipment from voltage spikes and lightning surges. Essential for installations in areas with unstable power supply.

13. Fuse

Basic overcurrent protection – melts when current exceeds rating to protect circuits. Available in various types including fast-blow and slow-blow.

14. Thermal Overload Relay

Prevents motor overheating damage by monitoring current and tripping when overloaded. Adjustable current settings match different motor ratings.

Control & Switching Components

15. Emergency Stop Switch

Safety-critical component for immediate power cutoff in emergency situations. Required by safety standards and must be easily accessible.

16. Selector Switch

Used to switch between circuit states or power sources (Auto/Manual, Local/Remote). Essential for operational mode selection.

17. Push Button

Manual control for circuit switching or signal sending. The Siemens 3SU1000-0AB30-0AA0 is a typical momentary pushbutton for control panels.

18. AC Contactor

Controls AC motor starting and stopping. Rated for high current switching applications with mechanical and electrical durability.

PLC & Control Systems

19. PLC – Programmable Logic Controller

The brain of automation systems. Siemens S7 series (S7-1200, S7-1500) are industry leaders for logic programming and device control. The 6ES7512-1CK01-0AB0 is a popular S7-1500 compact CPU, and the 6ES7195-7DH10-0XA0 provides PROFIBUS DP connectivity. For high-speed control applications, the 6DD1600-0BA1 SIMATIC TDC CPU delivers exceptional performance.

20. HMI Touch Panel

Human-machine interface for equipment operation and status display. Siemens SIMATIC HMI panels like the 6AV6643-0CB01-1AX1 are widely used in factory automation for intuitive operator control.

21. Terminal Block

Centralized connection point for organizing and managing electrical wiring in control cabinets. Proper terminal arrangement simplifies troubleshooting and maintenance.

Communication Components

22. Industrial Ethernet Switch

Network communication hub connecting multiple devices. The Siemens 6GK5208-0BA10-2AA3 and RS900G-HI-D-2SFP support PROFINET and Industrial Ethernet protocols.

23. Communication Module

Enables PLC communication with other devices via various protocols (PROFIBUS, PROFINET, Modbus). The 6DD1661-0AD0 and C73040-A27-C247-4 are designed for high-speed data exchange.

Motor & Drive Components

24. AC Motor

Converts electrical energy to mechanical energy. The workhorse of industrial machinery. The Siemens A5E00301347 provides motor control power board functionality.

25. Variable Frequency Drive (VFD)

Controls motor speed for energy savings and precise speed regulation. Siemens SINAMICS drives are industry standard. The 6SE7023-4EC84-1HF3 is a control driver module for drive systems.

26. Servo Motor

High-precision motor for accurate speed and position control in CNC, robotics, and packaging machines. Requires servo drive and feedback encoder for closed-loop control.

27. Stepper Motor

Pulse-controlled motor for precise positioning applications without feedback. Cost-effective solution for applications not requiring high-speed or high-torque.

28. Encoder

Measures rotation angle or speed, providing feedback for motor control systems. Available in incremental and absolute types for different positioning requirements.

Sensor Components

29. Limit Switch

Detects mechanical position of moving parts. Used for end-of-travel detection and safety interlocking in automated machinery.

30. Photoelectric Sensor

Detects object presence or position using light signals. Used for counting, detection, and positioning in conveyor and packaging systems.

31. Magnetic Switch

Detects magnetic object position, commonly used for pneumatic cylinder position sensing. Provides reliable feedback for cylinder extended/retracted status.

Process Control Components

32. Temperature Controller

Maintains equipment within set temperature range. Essential for process control applications in heating, cooling, and climate control systems.

33. Solenoid Valve

Electromagnetically controlled valve for pneumatic or hydraulic systems. Converts electrical signals to mechanical fluid control action.

34. EMC Filter

Filters electrical interference and noise from circuits, ensuring stable operation. Critical for environments with variable frequency drives and other noise sources.

Summary

These components form the foundation of Siemens automation systems and industrial control in general. Understanding how each component works and interacts is essential for designing automation systems, troubleshooting equipment faults, maintaining industrial machinery, and programming PLC applications.

Need Siemens Spare Parts?

We supply genuine Siemens PLC modules, HMI panels, power supplies, communication modules, and other automation components. Contact us for pricing and availability.