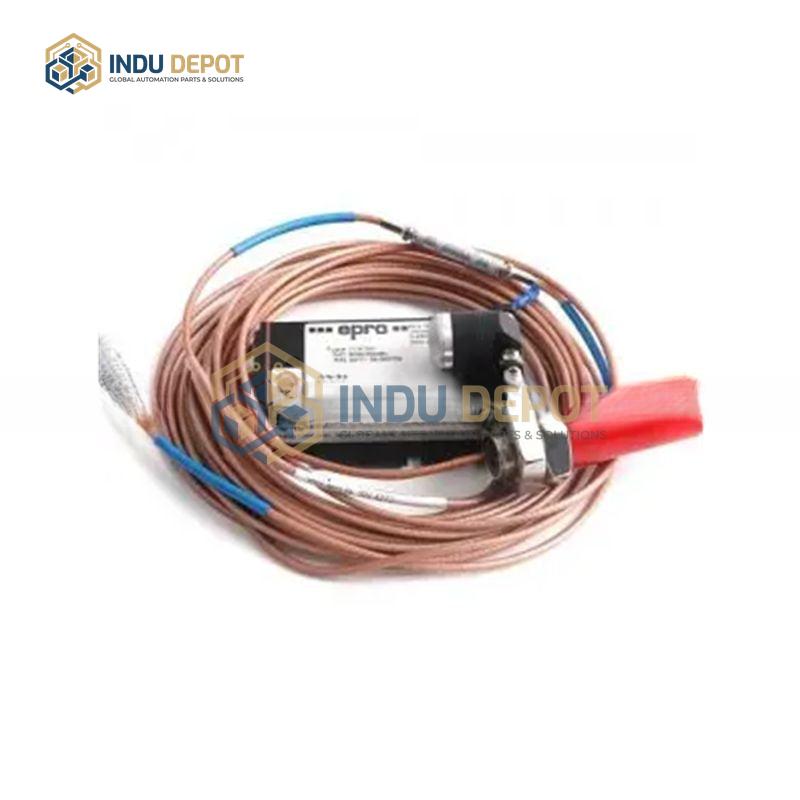

CON021 + PR6424/001-110 Eddy Current Sensor System EPRO

Description

TheEPRO CON021is aprecision signal converterdeveloped byEmerson(formerlyEPRO) for use with thePR642x series non-contact eddy current sensors. It converts theraw analog signalsfrom the probes into standardized output signals (such as4-20 mAor0-10 V DC), allowing for seamless integration withcontrol systems,protection relays, andcondition monitoring platforms. This converter is deployed across various critical applications such assteamandgas turbines,hydroelectric generators, andindustrial compressors, where accurateshaft displacementandvibrationmeasurements are essential forpredictive maintenanceandmachine protection. Its high-frequency range and fast response time make it ideal fordynamic fault detectionandhigh-speed applications. TheCON021is built with arugged design,wide operating temperature range, and anIP65-rated enclosure, ensuring reliable performance inharsh industrial environments. Furthermore, it is compatible with a wide range of sensor models, includingPR6422,PR6423,PR6424,PR6425,PR6426, andPR6453, making it highly flexible and suitable for various asset types. TheEPRO PR6424/001-110is an advancededdy current sensor systemdesigned forcontinuous condition monitoringin criticalturbomachineryapplications such assteam turbines,compressors, andhydroelectric generators. Utilizingeddy current technology, it provides precise measurement ofradialandaxial shaft movement, enablingearly fault detectionandpredictive maintenance. The sensor’sstainless steel housingandIP68 protection ratingensure long-term durability and reliable operation even inhigh-temperatureandhigh-vibration environments. Itsnon-contact designreduces mechanical wear, significantly lowering maintenance costs and increasinguptime. As part ofEmerson’s AMS suite, thePR6424/001-110reflects the company’s legacy ofengineering excellenceandreliability. This sensor system is widely used inpower generation,petrochemical, andheavy manufacturingsectors, helping to monitor machinery conditions and improve operational safety. ThePR6424/001-110offers outstandingfrequency responseandlinearity, making it ideal for dynamic shaft monitoring in complex rotating machinery. Additionally, itsCON021 signal converterprovides afast rise timeforreal-time diagnosticsand seamless data integration with plant-wide monitoring systems. Steam and Gas Turbines: Monitorsshaft movementandvibrationto prevent faults and optimize performance. Compressors and Pumps: Tracksdynamic displacementto detectimbalances,misalignments, and potential failures. Fans and Gearboxes: Detectseccentricityandmisalignmentin rotating components, preventing costly downtime. Hydroelectric Equipment: Ensures safe operation ofturbine shaftsand other critical components under variable load conditions. For example, inrefinery settings, thePR6424/001-110can identifyimbalanceandmisalignmentbefore they escalate into major issues, thus preventing costly repairs or shutdowns. Q: What is the measurement range of the PR6424/001-110?A:It measuresshaft displacementup to4.0 mm(standard) or6.0 mm(extended) for enhanced versatility. Q: Is this sensor compatible with other converters?A:ThePR6424/001-110isoptimizedfor use with theCON021 signal converter, which ensures optimal performance and signal integrity. Q: Can it operate in high-temperature environments?A:Yes, the sensor operates reliably in environments up to+100°C, making it suitable for demanding industrial applications. Q: What industries commonly use this sensor?A:ThePR6424/001-110is ideal for industries such aspower generation,oil & gas,chemical processing, andheavy manufacturing. Q: How is the sensor installed?A:The sensor is mounted near therotating shaftwith a fixed gap, usingstandard bracketsandcoaxial connectorsto ensure easy installation and integration.